Contact Us

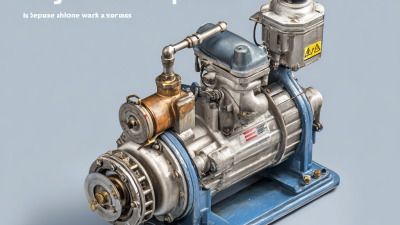

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

In the ever-evolving landscape of industrial efficiency, the importance of choosing the right steam condensate return pump cannot be overstated. As we advance into 2025, organizations across various sectors are recognizing the need to optimize their systems to not only reduce energy consumption but also enhance operational reliability. Expert James Thornton, a leading consultant in thermal management solutions, emphasizes this crucial point: "A well-selected steam condensate return pump can significantly reduce operational costs and improve system performance."

With the increasing pressure to meet sustainability goals, industries are turning to innovative solutions that streamline thermal processes and recover valuable energy from condensate. The right steam condensate return pump ensures that valuable steam is not wasted and that condensate is efficiently returned to the heating system. This not only conserves energy and resources but also contributes to a more eco-friendly operational approach.

As we delve into the "Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025," we aim to highlight the most effective and reliable options available. By examining these top contenders, businesses can make informed decisions that enhance productivity, minimize downtime, and promote a more sustainable future.

Top Features to Look for in 2025 Steam Condensate Return Pumps for Enhanced Efficiency

When selecting steam condensate return pumps in 2025, efficiency features will play a vital role in optimizing system performance. One key aspect to consider is the pump's energy consumption. Look for pumps equipped with variable frequency drives (VFDs), which can adjust the motor speed to match the flow requirements, reducing energy use during periods of low demand. Additionally, high-efficiency motors can further minimize energy costs while maximizing performance, ensuring that your system operates seamlessly.

Another important feature is the pump's material composition. Corrosion-resistant materials, such as stainless steel, can extend the lifespan of condensate return pumps by withstanding the harsh conditions typically associated with steam systems. Moreover, advanced design features like integrated check valves and automatic air venting can enhance functionality by improving flow dynamics and reducing potential bottlenecks in the system. By prioritizing these features, users can significantly enhance efficiency and reliability in their steam condensate systems for years to come.

Understanding the Importance of Condensate Return Pumps in Steam Systems Optimization

In steam systems, condensate return pumps play a crucial role in optimizing energy efficiency and enhancing overall performance. These pumps facilitate the return of condensate to the boiler, reducing water and energy waste while improving system reliability. As industries strive for sustainability, the significance of efficient condensate management becomes increasingly evident. Implementing modern condensate return pumps not only conserves resources but also supports operational cost reductions, aligning with the trend toward greener technology.

The recent energy recovery and heat pump systems installation at a prominent real estate establishment highlights the criticality of optimizing steam systems. By utilizing advanced pumps, facilities can effectively reduce their energy loads and enhance electrification efforts. This case underscores a growing commitment to sustainable solutions, where condensate return pumps emerge as vital components. As we look to 2025, integrating such technology will be essential for businesses aiming to meet both energy efficiency goals and regulatory standards, making the choice of the right pump more important than ever.

Evaluating Energy Savings: How Modern Pumps Lower Operational Costs in 2025

The significance of energy efficiency in industrial operations cannot be overstated, especially as companies seek to lower operational costs while meeting sustainability goals. In 2024 to 2025, £107.7 million was allocated for projects focused on energy efficiency and renewable energy initiatives. Such investments are crucial as advanced steam condensate return pumps exemplify how modern technology can significantly diminish energy consumption and operational expenses. By integrating these pumps, facilities can expect to optimize steam systems, resulting in energy savings of up to 20% according to industry analyses.

Moreover, embracing strategies that reduce energy costs is increasingly important for commercial and industrial (C&I) facilities. Implementing smart energy management systems allows for real-time monitoring of energy use and identifying inefficiencies. Studies indicate that strategic adjustments in system operations can lead to a decrease in energy expenses by as much as 30%. As industries move towards more environmentally conscious operations, these energy-efficient technologies and methodologies will play a pivotal role in shaping a sustainable future while also providing substantial financial benefits.

Innovations in Pump Technology: Key Trends to Watch in the Steam Industry

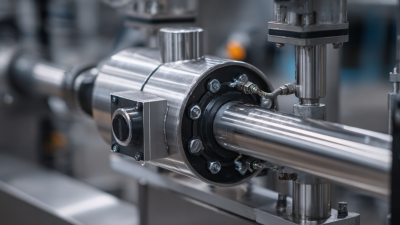

The steam industry is witnessing significant innovations in pump technology, crucial for optimizing condensate return systems. One of the key trends is the integration of advanced monitoring systems. Smart sensors and IoT connectivity allow for real-time data collection and analysis, empowering operators to make informed decisions about pump performance and maintenance. This technology not only reduces downtime but also enhances energy efficiency by ensuring pumps operate under optimal conditions.

The steam industry is witnessing significant innovations in pump technology, crucial for optimizing condensate return systems. One of the key trends is the integration of advanced monitoring systems. Smart sensors and IoT connectivity allow for real-time data collection and analysis, empowering operators to make informed decisions about pump performance and maintenance. This technology not only reduces downtime but also enhances energy efficiency by ensuring pumps operate under optimal conditions.

Another noteworthy development is the shift towards more sustainable materials and designs. Manufacturers are focusing on eco-friendly solutions, such as pumps made from recyclable materials and designs that minimize energy consumption. Furthermore, the trend of modular pump systems is gaining traction, allowing for easier upgrades and maintenance, thereby extending the lifespan of equipment. These innovations in pump technology not only improve operational efficiency but also align with the industry's growing commitment to sustainability and environmental responsibility.

Case Studies: Successful Implementation of Condensate Return Pumps in 2025

In 2025, numerous industries have benefited from the strategic implementation of steam condensate return pumps, leading to significant energy savings and enhanced operational efficiency. Case studies from manufacturing plants show that integrating advanced condensate return systems has reduced steam generation costs by up to 25%. For instance, a prominent automotive manufacturer adopted a state-of-the-art condensate return pump that optimized its heating processes, enabling them to repurpose over 80% of the condensate back into the system. This not only minimized waste but also improved their overall thermal efficiency.

Another compelling case comes from a food processing facility that faced challenges with condensate loss impacting production uptime. By installing a high-efficiency condensate return pump, the facility experienced a remarkable decrease in water and energy consumption, translating to cost savings and an increase in production reliability. The implementation allowed for real-time monitoring and adjustments, further fine-tuning the system's performance. Such case studies illustrate the transformative potential of condensate return pumps in various sectors, paving the way for more sustainable practices in the industrial landscape.

Related Posts

-

What is a High Pressure Water Pump and How Does It Work

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries