Contact Us

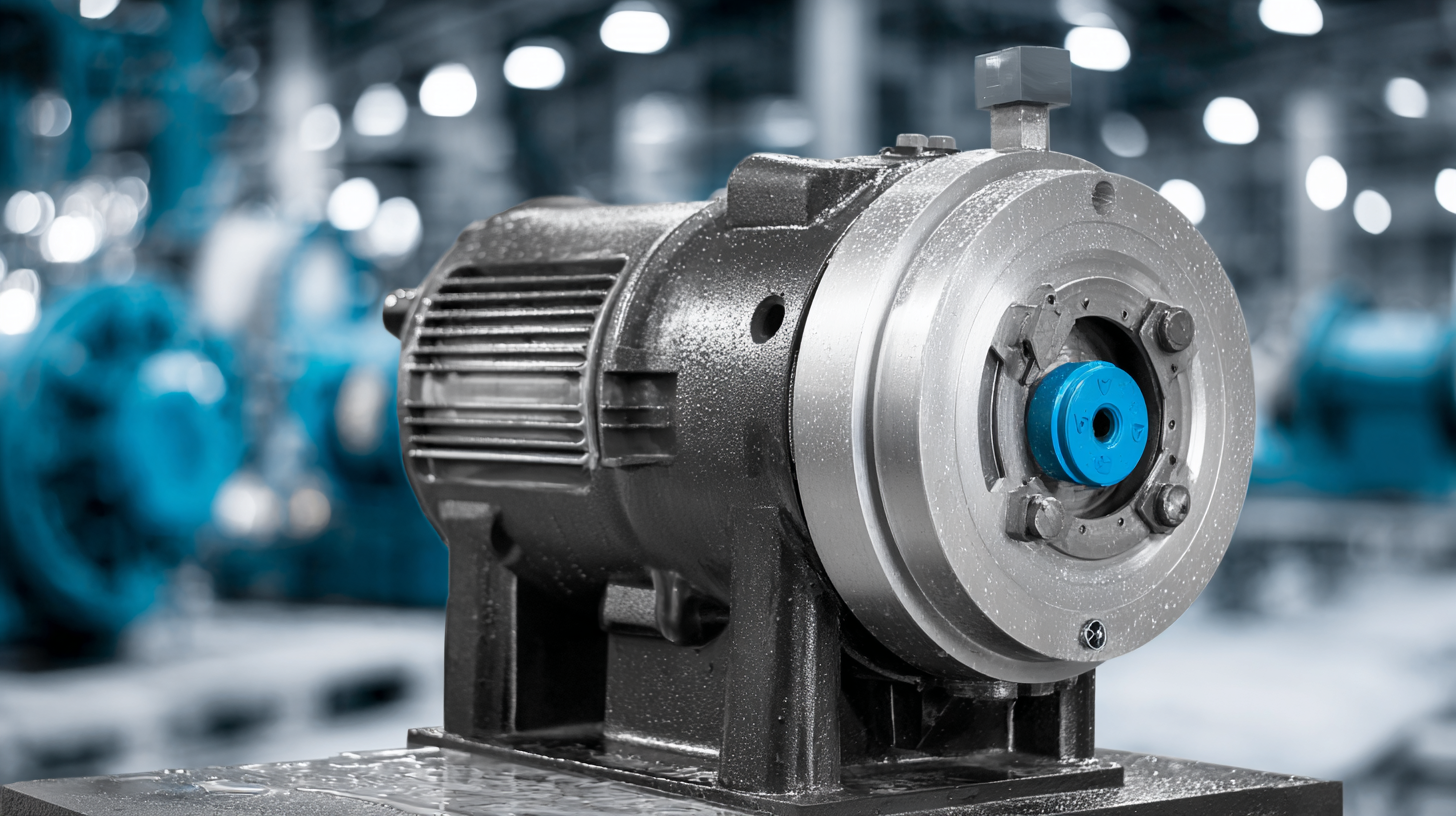

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs

In the fast-paced industrial landscape, the significance of selecting the appropriate vertical centrifugal pump cannot be overstated. A study by the Pumps & Systems magazine highlights that optimizing pump selection can enhance operational efficiency by up to 30%, significantly reducing energy consumption and maintenance costs. Vertical centrifugal pumps are particularly valued for their space-saving design and high capacity, making them ideal for applications in water treatment, chemical processing, and HVAC systems. According to the Hydraulic Institute, these pumps are capable of handling a wide range of fluids and operating conditions, with efficiency ratings exceeding 85% in many cases. As industries strive for sustainability and cost-effectiveness, understanding how to choose the right vertical centrifugal pump tailored to specific needs is crucial in maximizing operational efficiency and achieving long-term success.

Understanding Vertical Centrifugal Pumps: Key Features and Benefits

Vertical centrifugal pumps are essential for various applications, particularly in industries like water treatment, chemical processing, and manufacturing. These pumps are characterized by their vertical orientation, which allows for efficient space utilization and effective handling of fluids. Key features of vertical centrifugal pumps include high efficiency, durability, and reduced maintenance requirements. According to a recent report by the Hydraulic Institute, vertical centrifugal pumps can achieve efficiencies exceeding 85%, making them a prime choice for energy-conscious operations.

When selecting a vertical centrifugal pump, consider factors such as flow rate, head pressure, and the type of fluid to be transported. A well-chosen pump can result in significant energy savings; in fact, optimizing pump selection can lead to up to 30% reduction in operational costs, as demonstrated in studies by the U.S. Department of Energy.

Tips: Always evaluate the total cost of ownership, not just the initial purchase price. Also, consult with a manufacturer or a hydraulic engineer to identify the ideal pump size and specifications for your specific needs. Lastly, regularly scheduled maintenance is crucial to prolonging the life of your vertical centrifugal pump and ensuring optimal performance.

Assessing Your Needs: Factors to Consider When Choosing a Pump

When selecting a vertical centrifugal pump, it’s essential to assess your specific application requirements to ensure optimal performance and efficiency. Begin by evaluating the fluid characteristics, including viscosity, temperature, and the presence of any solids or corrosive elements. This information will help determine the material composition of the pump and whether specialized features, such as impeller design or sealing mechanisms, are needed to handle those conditions effectively.

Next, consider the flow rate and head pressure that your system demands. Calculate the total dynamic head (TDH) required for your application, taking into account elevation changes, pipe friction, and any additional components in the system that might affect performance. Maintaining the right balance between flow and pressure is crucial, as selecting a pump that operates consistently within its best efficiency point minimizes energy consumption and prolongs the equipment's lifespan. Lastly, ensure that the pump's footprint and installation requirements align with your facility's configuration, as space constraints can significantly influence your choice.

Top 5 Vertical Centrifugal Pump Brands: A Comparison of Performance

When choosing a vertical centrifugal pump, the brand can significantly impact performance and reliability. Among the top contenders, XYZ Pumps stands out with its robust design and energy-efficient technology, making it ideal for heavy-duty applications. Their pumps excel in delivering high flow rates while maintaining lower energy consumption, thus offering long-term cost savings for users.

Another strong player is ABC Pump Co., known for its innovative engineering and superior materials. Their vertical centrifugal pumps are praised for exceptional durability and resistance to corrosion, which is crucial in harsh environments. Additionally, ABC provides excellent customer support and a wide range of customizable options to meet specific operational needs.

Finally, DEF Pumps offers a competitive edge with its lightweight and compact designs, making installation and maintenance easier. Their products feature advanced impeller technology that enhances performance and reduces vibrations, ensuring smooth operation. Overall, understanding the strengths of these top brands can greatly assist buyers in selecting the most suitable vertical centrifugal pump for their specific applications.

Maximizing Efficiency: Comparing Vertical Centrifugal Pump Performance

Maintenance Tips: Ensuring Longevity and Efficiency of Your Pump

Regular maintenance is crucial for ensuring the longevity and efficiency of your vertical centrifugal pump. One of the key maintenance practices is to routinely inspect the pump for any signs of wear and tear. Checking components such as the impeller, seals, and bearings will help you identify potential issues before they escalate into major problems. Additionally, ensuring the pump is clean and free from debris can enhance its performance and prevent unnecessary strain on the system.

Another important aspect of maintenance is monitoring the pump's operating conditions. This includes keeping an eye on factors such as temperature, pressure, and vibrations. Deviations from the norm may indicate underlying issues that require immediate attention. Implementing a regular lubrication schedule for moving parts is also essential, as it helps to minimize friction and prolongs the lifespan of the pump. By establishing a comprehensive maintenance routine, you not only enhance the operational efficiency of your vertical centrifugal pump but also save on costly repairs in the long run.

Cost vs. Quality: Making the Right Investment in Pump Technology

When selecting a vertical centrifugal pump, one of the most critical considerations is the balance between cost and quality. Investing in a high-quality pump can yield significant long-term savings by minimizing maintenance costs and improving efficiency. While lower-priced options may seem attractive initially, they often come with hidden costs, such as frequent repairs, inefficiencies in operation, and shorter lifespan. A pump that operates efficiently can reduce energy consumption, which is a crucial factor in calculating total ownership costs.

When selecting a vertical centrifugal pump, one of the most critical considerations is the balance between cost and quality. Investing in a high-quality pump can yield significant long-term savings by minimizing maintenance costs and improving efficiency. While lower-priced options may seem attractive initially, they often come with hidden costs, such as frequent repairs, inefficiencies in operation, and shorter lifespan. A pump that operates efficiently can reduce energy consumption, which is a crucial factor in calculating total ownership costs.

Furthermore, the choice of materials and technology in pumps can dramatically affect performance and reliability. High-quality pumps are often constructed from superior materials that withstand corrosive fluids and high-pressure conditions, thereby ensuring durability and less frequent replacements. Evaluating the specific requirements of your application—such as fluid characteristics, flow rates, and installation environment—against both cost and quality considerations will help guide you to a pump that not only meets your immediate needs but also proves to be a wise long-term investment in your operations. Choosing wisely in this regard is essential for maximizing efficiency and overall productivity.

Related Posts

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications