Contact Us

What is a High Pressure Water Pump and How Does It Work

High pressure water pumps are essential tools widely used across various industries, from construction to agriculture, enabling the effective movement and pressurization of water. According to a recent report by the Global Water Pump Market, the high pressure water pump segment is projected to grow at a CAGR of 5.2% from 2021 to 2028, highlighting the increasing demand for efficient water management solutions. Industry expert Dr. Emily Carson noted, "The effectiveness of high pressure water pumps is critical in enhancing operational efficiency and meeting environmental standards across sectors."

Understanding how a water pump high pressure operates is vital for selecting the right equipment for specific applications. These pumps typically employ advanced mechanisms to create a significant pressure differential, allowing for the transfer of water over long distances or against significant resistance. Moreover, proper maintenance and selection of high-pressure systems can lead to reduced energy consumption and prolonged equipment lifespan. As the industry evolves, ongoing innovations and technological advancements promise to further enhance the capabilities and efficiency of high pressure water pumps, setting new standards in performance and sustainability.

What Defines a High Pressure Water Pump in Various Applications

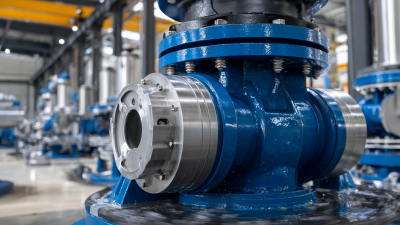

A high pressure water pump is an essential tool across various industries, characterized by its ability to generate water at elevated pressures. These pumps are typically defined by their capacity to deliver water with a pressure range exceeding 100 PSI (pounds per square inch). Their design allows for efficient fluid movement, making them ideal for applications ranging from agricultural irrigation and industrial cleaning to fire suppression systems.

In agriculture, high pressure water pumps are vital for effective irrigation processes, allowing farmers to distribute water evenly across large fields. In industrial settings, these pumps are prevalent in cleaning operations, where they can dislodge dirt and grime from machinery and surfaces with high efficacy. Additionally, in firefighting, high pressure pumps are crucial in delivering large volumes of water quickly to combat flames. Overall, the versatility of high pressure water pumps makes them indispensable in applications that demand reliable performance under pressure.

High Pressure Water Pump Applications

This chart illustrates the pressure levels (measured in psi) at which high pressure water pumps operate across various applications. These pressure levels are crucial for understanding the effectiveness and suitability of different pumps in specific tasks.

The Essential Components of a High Pressure Water Pump Explained

A high-pressure water pump is a crucial apparatus widely used in various applications, from industrial cleaning to irrigation systems. Its essential components primarily include the motor, pump head, pressure switch, and valves. The motor drives the pump head, creating the necessary force to elevate water pressure. According to a recent industry report by Grand View Research, the global high-pressure pump market is projected to grow at a CAGR of 5.4% from 2021 to 2028, underscoring the increasing demand for efficient water pressure solutions.

The pump head consists of impellers and diffusers designed to accelerate water, resulting in increased pressure. Pressure switches monitor the system and ensure consistent operation by automatically activating or deactivating the pump based on the pressure levels. Valves play a critical role in controlling water flow and maintaining appropriate pressure within the system. Understanding these components is essential for anyone working with or purchasing high-pressure water pumps, as each part influences the performance and efficiency of the pump.

**Tips:** When selecting a high-pressure water pump, consider the maximum flow rate and pressure requirements for your specific application. Regular maintenance of the pump and its components will help prolong its lifespan and ensure optimal performance. Additionally, investing in quality components will lead to better efficiency and reliability, saving you time and costs in the long run.

What is a High Pressure Water Pump and How Does It Work - The Essential Components of a High Pressure Water Pump Explained

| Component | Description | Function |

|---|---|---|

| Pump Housing | The external casing that houses internal components | Provides structural support and protection for the pump internals |

| Impeller | A rotating component that increases the pressure of the water | Converts mechanical energy into hydraulic energy |

| Suction Strainer | Filters out debris before water enters the pump | Prevents clogging and damage to internal components |

| Check Valve | Allows fluid to flow in one direction only | Prevents backflow which can cause damage |

| Pressure Gauge | Instrument that measures the output pressure of the pump | Provides feedback for system monitoring and control |

| Motor | Drives the impeller to create water flow | Converts electrical energy into mechanical energy |

How High Pressure Water Pumps Generate Forceful Water Streams

High pressure water pumps are essential for generating powerful water streams used in a variety of applications, from agriculture to firefighting. These pumps work by compressing water through a series of mechanical components designed to create high velocity. When water is forced through a narrow outlet, it accelerates, resulting in a concentrated stream capable of tackling tough challenges, such as creating thermal refuges for aquatic species or combating wildfires effectively.

To enhance the power of a standard shower, consider installing a high-pressure shower head. This addition can dramatically improve your shower experience by maximizing water flow and providing a more invigorating rinse. Another tip is to clean your shower head regularly; mineral buildup can obstruct water flow, diminishing pressure. Lastly, if you're looking for an immediate solution, adding a small booster pump can provide that burst of pressure you need for an enjoyable shower, ensuring you start or end your day revitalized.

Common Uses of High Pressure Water Pumps Across Industries

High pressure water pumps are vital across various industries, offering solutions that range from cleaning to irrigation. According to a report by MarketsandMarkets, the global water pump market is projected to grow from USD 53.5 billion in 2020 to USD 72.9 billion by 2025, highlighting a significant demand for high pressure systems. These pumps are commonly used in applications such as power washing, where they can remove stubborn dirt and grime from surfaces, achieving pressures often exceeding 3,000 PSI.

In agriculture, high pressure water pumps facilitate precision irrigation systems, enhancing water delivery efficiency and crop yields. A study from the Food and Agriculture Organization states that improved irrigation methods have the potential to increase agricultural productivity by 20-50%. Additionally, in the manufacturing sector, these pumps play a crucial role in processes like cutting and surface preparation, significantly reducing labor costs and improving accuracy. Their ability to deliver water at high pressure makes them indispensable in ensuring operational efficiency and meeting industry standards.

Maintenance Tips for Optimal Performance of High Pressure Water Pumps

Maintaining a high pressure water pump is crucial for ensuring its longevity and optimal performance. Regular maintenance checks should include inspecting the pump for any signs of wear or damage, particularly in the seals and hoses. It’s important to keep the intake screen clear of debris to prevent clogging, which can hinder water flow and cause the pump to operate inefficiently. Scheduling routine inspections can help identify potential issues before they escalate into significant problems.

Another essential aspect of maintenance is ensuring that the pump is adequately lubricated. Checking oil levels and replacing lubricants according to the manufacturer's recommendations can significantly improve performance. Additionally, periodic testing of the pressure output will help in monitoring the pump’s efficiency. If there are fluctuations in pressure, it might indicate a need for more in-depth servicing. Storing the pump properly during off-seasons and protecting it from harsh weather conditions can also help maintain its performance effectively. Consistent care leads to reliable operation and extends the life of high pressure water pumps.

Related Posts

-

7 Essential Tips for Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications

-

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry