Contact Us

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

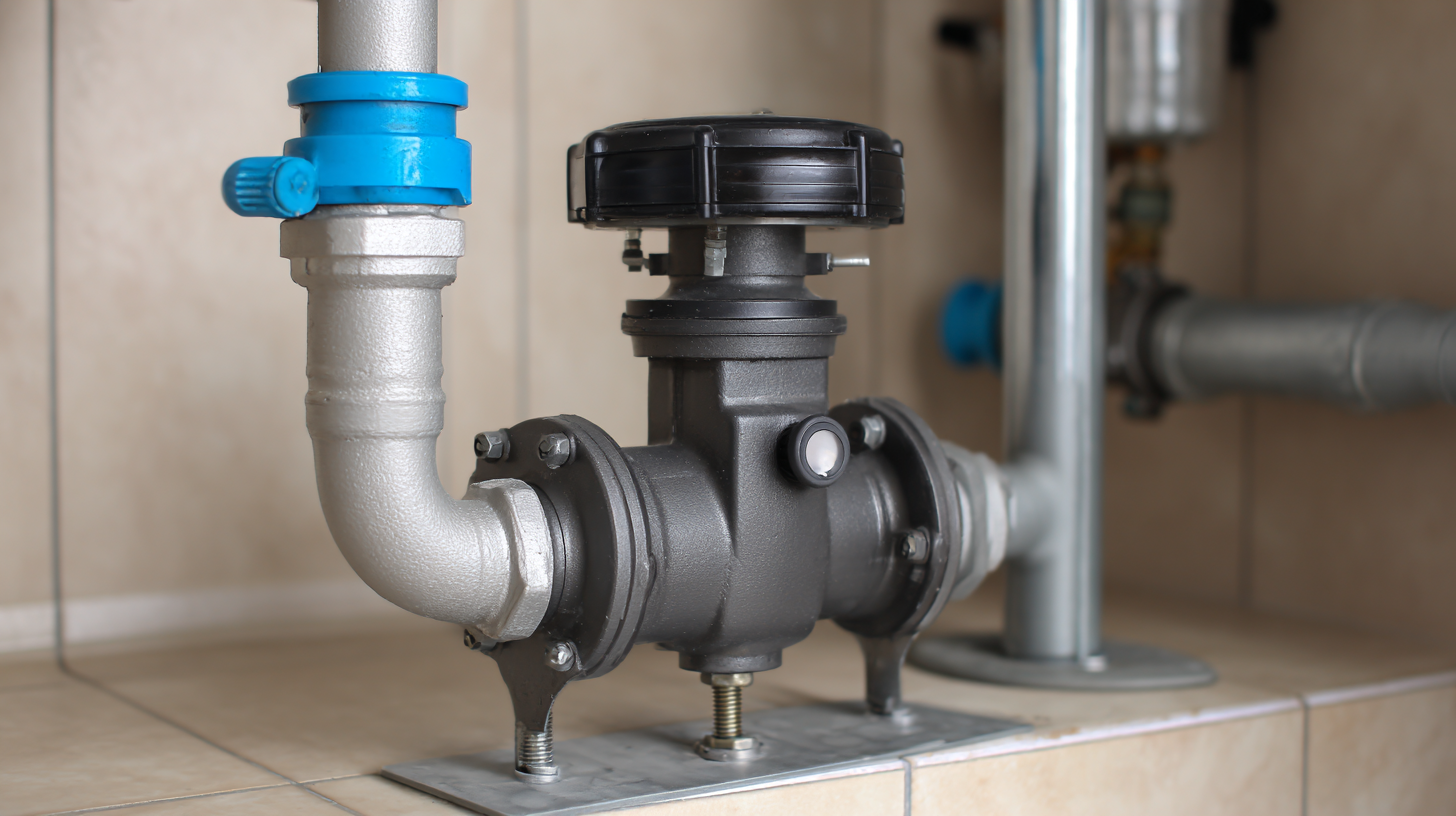

When it comes to maintaining the efficiency and longevity of your home heating system, selecting the right boiler condensate pump is crucial. This essential device plays a pivotal role in removing excess water produced by condensing boilers, preventing damage to your property and ensuring optimal performance. With a multitude of options available on the market, choosing the ideal boiler condensate pump can be overwhelming. In this article, we will guide you through seven essential tips that will help you make an informed decision tailored to your specific needs.

Understanding the function and importance of a boiler condensate pump is the first step in the selection process. These pumps help manage the water that accumulates as a byproduct of the heating process, which, if left unattended, can lead to severe water damage and inefficiency in your heating system. As you delve into the nuances of selecting the best boiler condensate pump for your home, consider factors such as pump capacity, installation requirements, and the unique characteristics of your heating system. By following our expert tips, you can ensure that you purchase a reliable and effective pump that not only meets your home's needs but also enhances your heating system's performance.

Factors to Consider When Assessing Boiler Condensate Pump Requirements

When assessing your boiler condensate pump requirements, several critical factors must be considered to ensure optimal performance and efficiency. First, the pump's capacity should match the volume of condensate produced by your boiler system. This measurement is typically expressed in gallons per hour (GPH). A pump with insufficient capacity may lead to frequent cycling, causing wear and inefficiency, while an oversized pump can lead to energy wastage and unnecessary costs.

Another vital consideration is the pump's head height, which refers to the vertical distance the condensate must be lifted. Understanding the total lift required from the boiler to the discharge point will help in selecting a pump that operates effectively without overexertion. Additionally, consider the materials used in the pump's construction—durability against corrosive condensate is essential. Finally, evaluate the noise levels and energy efficiency ratings of the pump, as these factors can significantly impact your overall comfort and utility costs in the long run.

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

| Factor | Details |

|---|---|

| Pump Type | Choose between submersible and non-submersible based on installation conditions. |

| Capacity | Assess the amount of condensate your boiler produces to match the pump capacity. |

| Head Height | Consider the height the pump needs to lift the condensate to avoid pump failure. |

| Power Source | Select the appropriate power supply, either electrical or battery-operated, per your needs. |

| Noise Level | Evaluate the sound rating to minimize disruption in residential areas. |

| Maintenance Requirements | Consider the ease of servicing and parts availability for long-term use. |

| Warranty & Support | Check the warranty period and customer support availability for troubleshooting. |

Understanding the Different Types of Boiler Condensate Pumps

When selecting a boiler condensate pump for your home, it's crucial to understand the different types available. The most common variants include cast iron pumps, which are known for their durability and ability to handle larger volumes of condensate. Stainless steel pumps are another option, offering corrosion resistance and a sleek appearance, making them suitable for residential settings. Additionally, there are submersible pumps that can be placed directly in the collection tank, allowing for efficient drainage without taking up excess space.

Tip 1: Always consider the pump's capacity to ensure it can handle your specific boiler’s condensate output. If the pump is undersized, it may fail to operate effectively, leading to overflow issues.

Tip 2: Look for energy-efficient models that can help reduce your overall energy costs. Many modern condensate pumps are designed to operate quietly and consume less power, making them an ideal choice for any home.

Tip 3: Don’t forget to check the warranty and customer support options. A good warranty reflects the manufacturer's confidence in their product, while responsive customer service can be beneficial for troubleshooting and maintenance in the long run.

Key Features to Look for in a High-Quality Condensate Pump

When selecting a high-quality boiler condensate pump for your home, there are several key features to consider that can significantly impact performance and reliability. First and foremost, the pump's capacity is crucial; ensure that it can handle the expected volume of condensate produced by your heating system. Pumps typically come with specifications that indicate their maximum flow rate and head height, so choose one that meets your home's specific requirements.

Another important feature is the material construction of the pump. High-quality pumps are often made from corrosion-resistant materials like stainless steel or durable plastic, ensuring longevity even in harsh conditions. Additionally, consider the power source and energy efficiency of the pump. Models that run quietly and consume less energy will not only save you money in utility bills but also contribute to a more comfortable living environment. Finally, look for features like automatic shut-off and easy maintenance access, which can enhance the user experience and prolong the life of your condensate pump.

Installation and Maintenance Tips for Optimal Performance

When selecting a boiler condensate pump, installation and maintenance play crucial roles in ensuring optimal performance. According to a report by the Heating and Hotwater Industry Council (HHIC), improper installation can reduce pump efficiency by up to 30%, leading to increased energy costs and potential system failures. It is essential to install the pump at the correct height and ensure that all piping is appropriately sloped to facilitate effective condensate drainage. Additionally, choosing a pump with a higher flow rate than the maximum expected can prevent overloading and prolong its lifespan.

Regular maintenance is equally important. The Institute of Mechanical Engineers highlights that routine checks and servicing can extend the life of a condensate pump by up to 50%. This includes inspecting the float switch, checking for blockages in the discharge line, and ensuring that the pump motor is functioning correctly. Furthermore, it is advisable to clean the pump tank periodically to prevent sludge buildup, which can hinder performance. By adhering to these installation and maintenance guidelines, homeowners can maximize the efficiency and longevity of their boiler condensate pumps.

Common Mistakes to Avoid When Selecting a Condensate Pump

When selecting a boiler condensate pump for your home, avoiding common mistakes is critical to ensure efficiency and longevity. One major error homeowners make is underestimating the required lift and flow rate. According to industry data, a condensate pump should ideally have a lift capacity of at least 20 feet for most residential applications. Failing to consider this can lead to inadequate drainage and potential water damage.

Another common pitfall is *neglecting to check* the pump's compatibility with your heating system. Many homeowners assume that all pumps will work universally, but variations in pressure requirements and temperature tolerance can significantly impact performance. Reports suggest that improper selection can lead to up to a 30% decrease in operational efficiency, highlighting the importance of aligning pump specifications with the requirements of existing heating systems. Prior research has shown that 50% of heat pump installations are flawed due to incorrect assessments of necessary equipment, emphasizing the need for thorough due diligence. Making informed choices ensures reliable operation and protects your investment in home heating technology.

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications